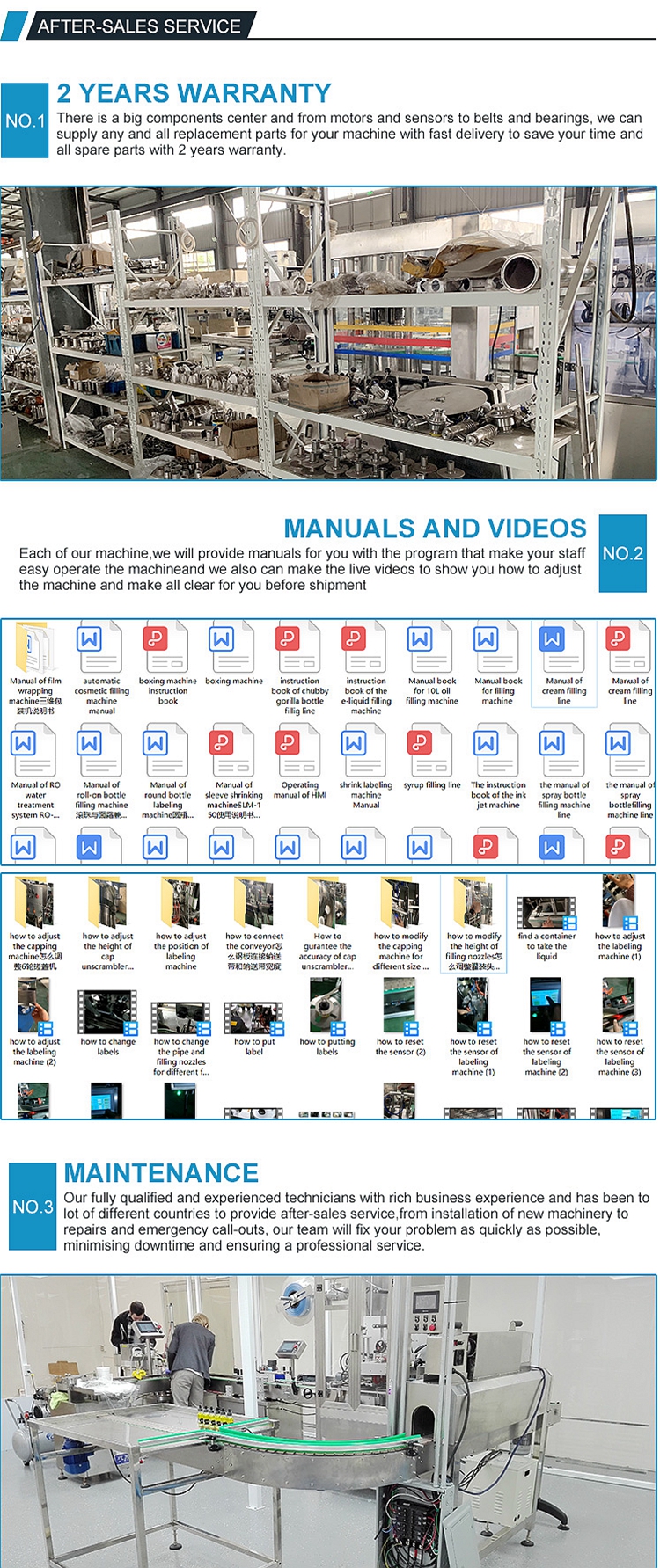

Description

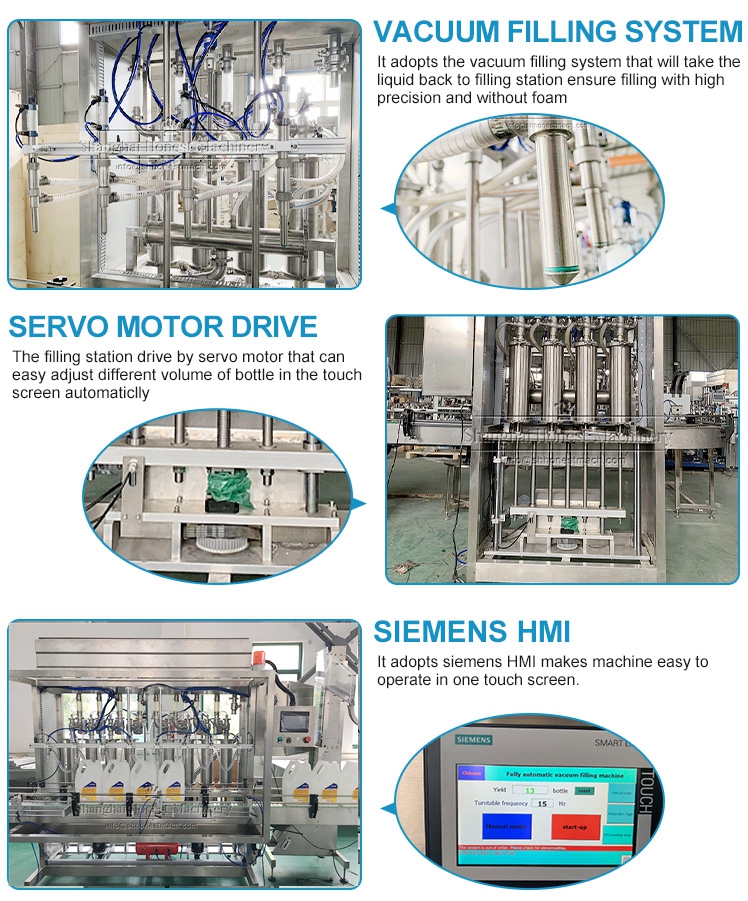

The Antifreeze filling machine is manufactured with a heavy duty 304 stainless steel, tigwelded tube frame and is available with 1 to16 Fill Heads.It also comes standard with PLC Controls and touch screen HMI,a 304 stainless steel reservoir, and Pneumatic Indexing Gates, plus many more features. Options are available for even more versatility.

The disinfectant filling machine/sterilizer liquid filling machine is commonly used in the food service, cleaning and specialty chemical, pharmaceutical, cosmetic and personal care industries for various filling projects.

|

Model |

Antifreeze filling machine |

|

Filling volume |

100-5000ml |

|

Filling nozzles |

1-12 nozzles for your optional |

|

Filling type |

Piston pump, flow meter(for your optional) |

|

Production capacity |

10-100 bottles per minute(for your optional) |

|

Filling accuracy |

±1%(according to product) |

|

Capping rate |

≥99.5% |

|

Power supply |

1 phase,220V 60/50Hz or 3 phase 380V |

|

Power |

3-5Kw |

|

Total dimension |

2450 * 1350 * 1950mm(Can be customized) |

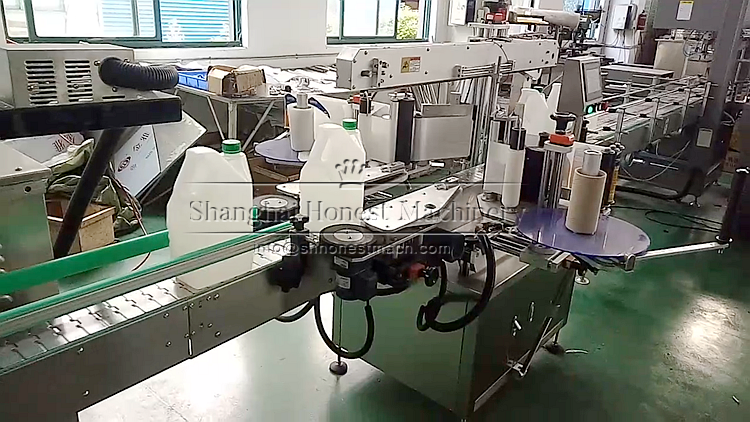

1.Suitable for various low viscosity material,and various shaped containers

2.All connections adopt quick release joint, easy to dismantle and maintain, reduce the cost of the use and maintenance, save the time

3.With self-cleaning system that can do cleaning automaticlly

4.HMI control,easy-to-use intuitive HMI touch screen controls for your operator

5.No container/no filling,no container/no cappping

6.Machine with overflow trough, avoid material leak,, ensure a clean and safe working environment.

7.Reduced labour costs

8.Whole machine made of SS304, with grace appearance.material contact part made of SS316.

9.Easy to adjust for different tape and shaped container,10 minutes can change all the parts.