Description

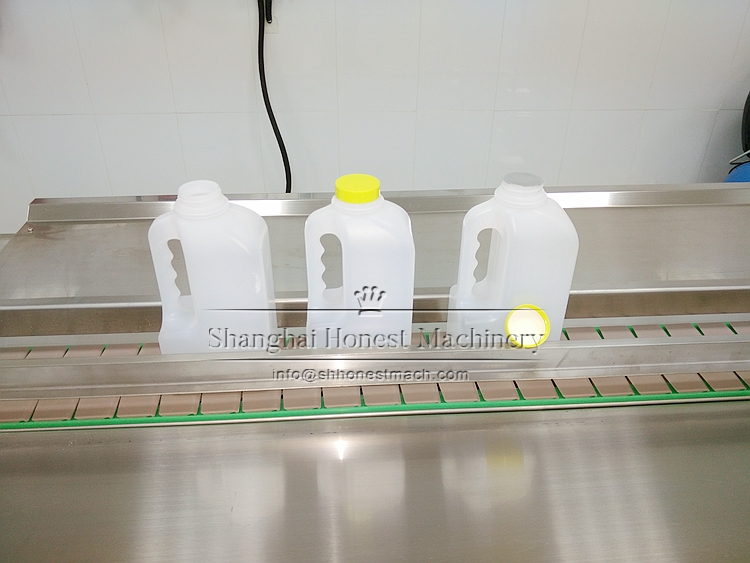

The powder filling and sealing machine adopt auger to measure and fill powder and granular, with high filling speed and filling accuracy. The auger is driven by servo motor. It fits more to the fluidic or low-fluidity materials, like nail dip powder, albumen powder, coffee powder pharmaceuticals, condiment, solid drink, white sugar, dextrose, coffee, agriculture pesticide, granular additive, and so on.

|

Model |

powder filling and sealing machine |

|

Filling volume |

50-5000g(can be customized) |

|

Filling nozzles |

1-8 nozzles for your optional |

|

Filling type |

Auger rotation filling |

|

Production capacity |

10-80 bottles per minute(for your optional) |

|

Filling accuracy |

10-100gr ≤±1%/ 100-1000g ≤±0.8%(depend on material and weight) |

|

Capping rate |

≥99% |

|

Power supply |

1 phase,220V 60/50Hz or 3 phase 380V |

|

Power |

3-5Kw |

|

Total dimension |

2450 * 1350 * 1950mm(Can be customized) |

1.Suitable for various low viscosity material,and various shaped containersThe surface of whole machine is made by stainless steel 304. Knockdown transparent hopper is easy cleaned.

2.This machine adopts 1 filling nozzle, and that adopts feed screw by touch screen, which is suitable for all kind powder materials, with high filling speed and high filing precision.

3.Main component: all use word-class famous brand, PLC Mitsubishi(Japan), photo sensor Omron(Japan) etc.

4.This Machine adopt auger to measure and fill powder and granular, with high filling speed and filling accuracy. The auger is driven by servo motor.